STEELMATE SL500

The choice of reliability, powerful and easy operation

| Quick Specs | |||

| Input Voltage | 3PH ~ 400V ±15% | ||

| Rated Output(40℃) 60% | 500A/39V | ||

| Cooling system

|

Air-cooled | ||

| Gas

|

CO2/MAG | ||

| Welding process | |||

| Solid wires (GMAW) | ● | ||

| Flux-cored (FCAW) | ● | ||

| Metal-cored (MCAW) | ● | ||

| Air carbon arc cutting & gouging (CAC-A) | ● | ||

| Stick (SMAW) | ● | ||

● Standard options ○ Optionally available

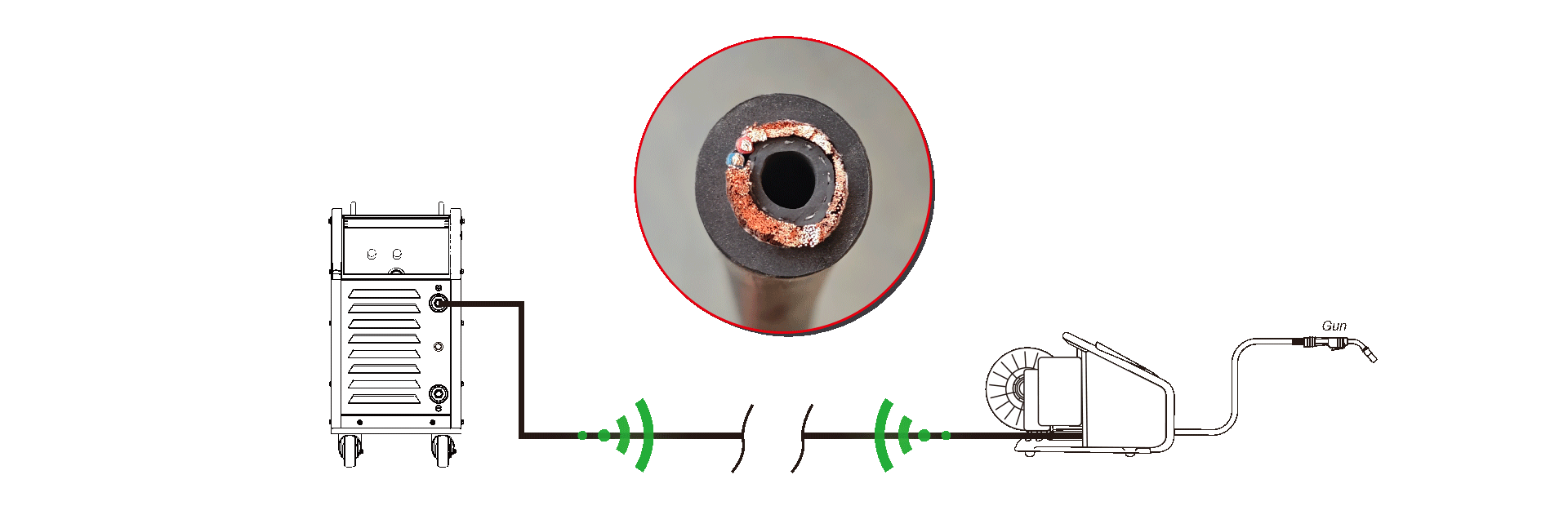

The advantage of the P-L-C technology

The Power Line Communication (PLC) is one kind of the Carrier Communication technologies that taken by the Topwell's special designed welding cable (Coaxial cable with built-in gas hose), can get a great advantage for the ultra-long welding applications (especially the ship building or steel constructions).

The key techno points of the Topwell’s PLC system:

Benefits:

Eliminate the extra cables

Ultra-long-distance welding with precise & stable arc controls

Excellent welding performance

Capable for future intelligent fabrication

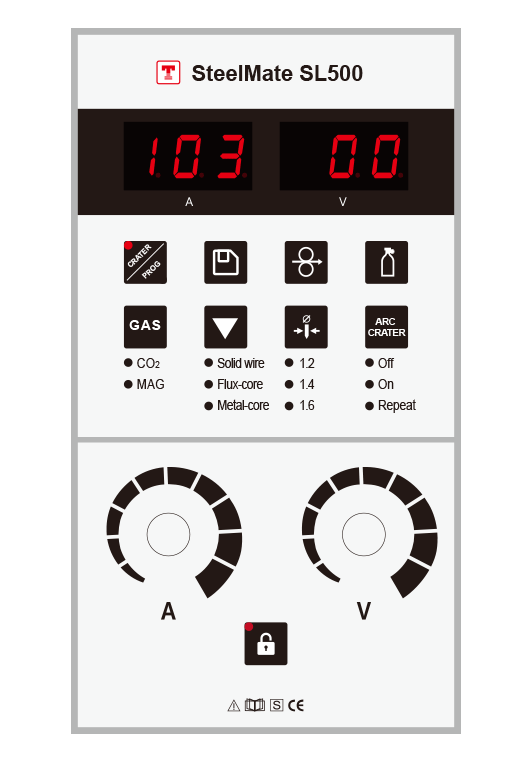

Optional user management

Steelmate SL series is equipped with active user management and assigned NFC keys to set protection and permissions for parameter adjustment.

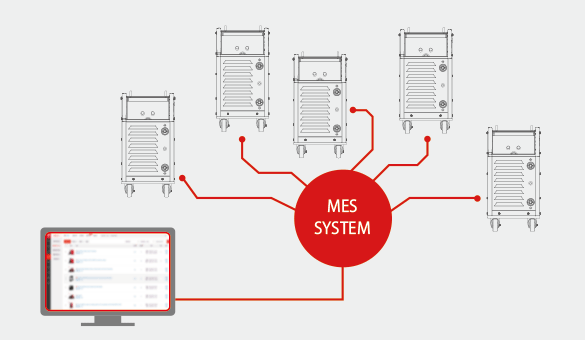

MES system

It can also choose to connect to the MES system, which is more suitable for modern production data management.

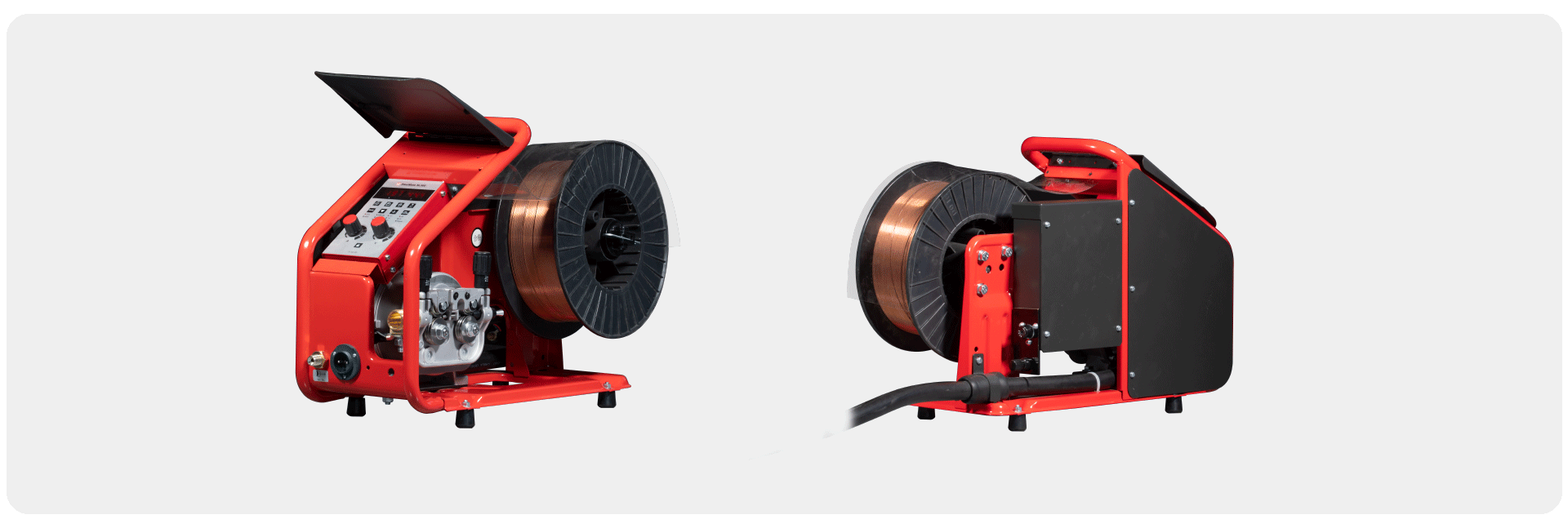

Optimized wire feeder

Innovative intermediate junction box

Long distancewelding work

Ultra-Long cable loop compensation function

Intelligent compensation makes welding more stable, especially suitable for oversized workpiece welding occasions.